Finally, everything starts again from the beginning.

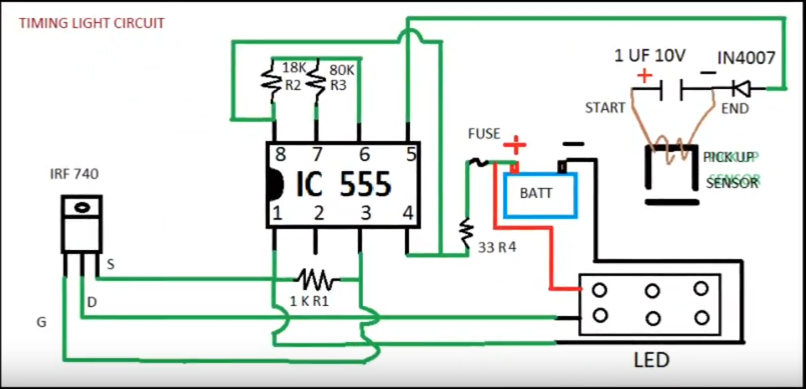

The Th1 thyristor doesn't remain open because the resistance in its anode circuit is quite high, meaning that the current flowing through the thyristor is way below its holding current. As soon as the C2 capacitor is fully discharged, the T1 transistor closes again and the LED goes out. The T1 transistor senses the voltage dropped on this resistor and opens, switching the LED to the +12 V supply (through a customary current limiting R5 resistor you might need to alter its value according to the current of the LED you actually use). The first pulse opens the thyristor and the C2 capacitor discharges through the R4 resistor. When the engine is running, the trigger input collects this signal via a capacitive coupling. Using a shielded cable for the trigger input line is essential to avoid false input from the other cylinders.Īs soon as you switch the circuit on, the C2 capacitor starts to charge with the current flowing through the R2 resistor but nothing else happens as the Th1 thyristor is initially closed. The trigger input must not be connected directly to the ignition system in any way, use an alligator clip clipped around the insulation of the first cylinder (closest to the distributor) spark plug HT lead. The +12 V and ground wires should be clipped to the battery terminals (the D1 diode protects the circuit from accidental reverse polarity). The functioning of the circuit is quite simple. We can spare all these components as our circuit will be perfectly happy to use the 12 V it receives from the car's battery. This converter used high voltage capacitors, diodes and a transformer.

The stroboscope circuit is also much simpler than the traditional one where a DC-DC converter was needed to generate the high voltage from the 12 V DC available. Such LEDs are about ten times more expensive than regular ones but in absolute figures that's not so terrible at all: around 3-5 EUR each. If you even put it into a socket with a reflector and a focusing lens, its light will be so bright that-although it's not a laser diode-you should never look directly into the light rays. These mostly AlInGaP (Aluminum-Indium-Gallium Phosphate) LEDs come with an intensity level in the range of 10,000 to 25,000 microcandelas, which is an awful lot compared to the 5-50 mcd value of common LEDs.

There are very high intensity LED diodes available which are perfectly suited for this task. Unless you have experience in building such high voltage circuits (including proper insulation) and also have measuring equipment to help with the process, you shouldn't even think of building one.įortunately, with the advances of contemporary semiconductor technology, there is no need for those flashlights. Needless to say, electric shocks of such voltages are often lethal. However, these flashlights require a 400-600 V voltage and even more for igniting them. Traditionally, stroboscopes were built with xenon flashlights such as those used in photographic flashguns.

0 kommentar(er)

0 kommentar(er)